Unveiling the Manufacturing Process of Magnetic Latches: A Deep Dive into Hardware Expertise

Welcome to our news, where we take you behind the scenes of the captivating world of hardware manufacturing. Here, we delve into the intricate process of creating magnetic latches, shedding light on the expertise and precision that goes into their production. As a hardware manufacturer, we are excited to share with you the secrets behind the manufacturing of these remarkable components. Join us on this journey to discover the artistry and technology that bring magnetic latches to life.

1. Design and Engineering:

The manufacturing process of magnetic latches begins with meticulous design and engineering. Skilled professionals, armed with industry knowledge and cutting-edge software, conceptualize and create detailed blueprints. These blueprints capture the dimensions, materials, and specifications required to produce magnetic latches that meet the highest standards of quality and functionality.

2. Material Selection:

Choosing the right materials is crucial in ensuring the durability and performance of magnetic latches. High-quality metals, such as stainless steel or zinc alloy, are commonly used for their strength and resistance to corrosion. These materials undergo rigorous testing to ensure they meet the desired standards of strength, flexibility, and magnetic properties.

3. Tooling and Manufacturing:

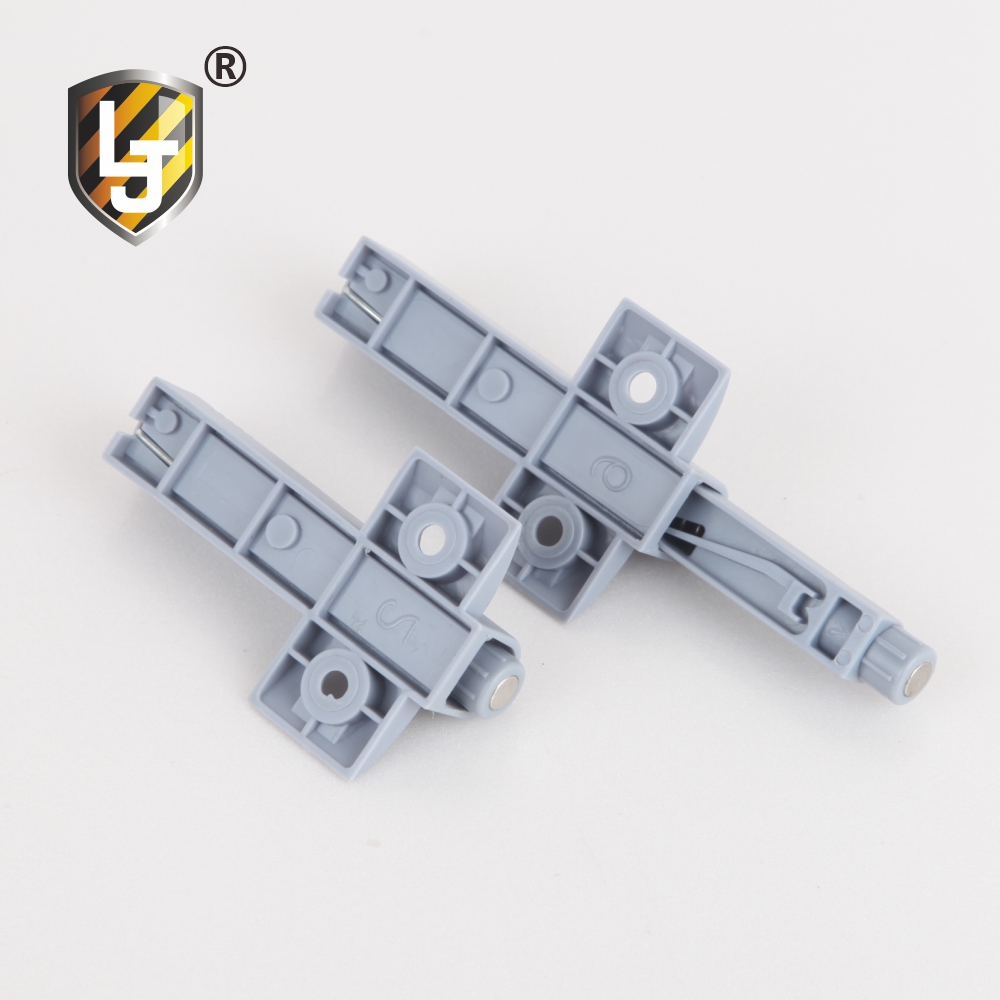

Once the design and material selection are finalized, the manufacturing process kicks into high gear. Specialized tools and machinery are employed to shape the raw materials into the desired components. Techniques like die casting, injection molding, or precision machining are utilized to achieve the intricate shapes and dimensions required for magnetic latches.

4. Surface Treatment:

To enhance the aesthetics and durability of magnetic latches, various surface treatment processes are employed. These processes include polishing, plating, or powder coating, which provide a protective layer against wear and tear, corrosion, and environmental factors. The surface treatment not only ensures a visually appealing finish but also extends the lifespan of the latches.

5. Assembly and Quality Control:

The assembly of magnetic latches involves expert technicians who meticulously fit together the various components. This process requires precision and attention to detail to ensure that the latches function smoothly and reliably. Stringent quality control measures are implemented at each stage of assembly to identify and rectify any defects, ensuring that only the highest-quality magnetic latches reach the market.

6. Testing and Certification:

Before magnetic latches are ready for distribution, they undergo rigorous testing to ensure their performance and compliance with industry standards. These tests include functionality assessments, durability tests, and magnetic force measurements. Once the latches pass these tests, they receive certifications that validate their quality and reliability.

Conclusion:

The manufacturing process of magnetic latches is a testament to the expertise, dedication, and advanced technology employed by hardware manufacturers. From the initial design and engineering stages to the final testing and certification, every step is carefully executed to produce magnetic latches of exceptional quality and functionality. As hardware experts, we take pride in our role in bringing these remarkable components to the market, enabling individuals and businesses to enhance the security and convenience of their spaces.

Next time you admire the seamless operation of a magnetic latch, remember the intricate manufacturing process that lies behind it. Stay tuned for more insights into the fascinating world of hardware manufacturing, where innovation and craftsmanship converge to create the products that shape our everyday lives.