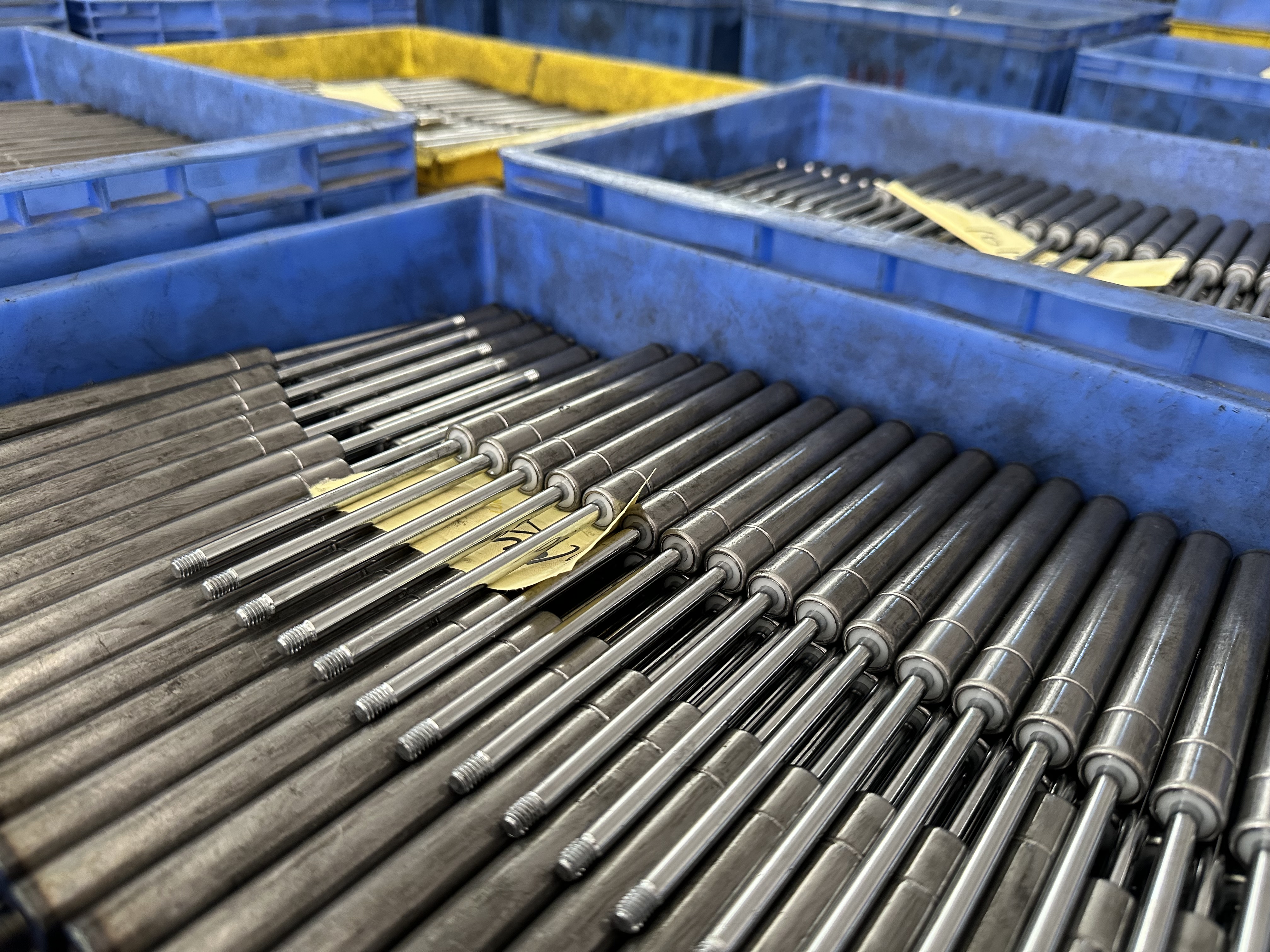

Unveiling the Inner Workings: Exploring the Main Components of Stainless Steel Gas Struts

Stainless steel gas struts are a reliable and versatile solution for supporting heavy lids in various industries. These struts are not only known for their strength and durability but also for their resistance to corrosion. In this article, we will take a closer look at the main components that make up a stainless steel gas strut, shedding light on their functions and contributions to the overall performance of these essential devices.

1. Stainless Steel Cylinder:

The cylinder serves as the outer casing of the gas strut, providing structural integrity and protection for the internal components. Made from stainless steel, the cylinder offers superior corrosion resistance, ensuring the longevity and durability of the gas strut even in harsh environments. The stainless steel cylinder also contributes to the overall strength of the strut, enabling it to handle heavy loads with ease.

2. Hardened Stainless Steel Piston Rod:

The piston rod is a critical component of the gas strut responsible for extending and retracting within the cylinder. In stainless steel gas struts, the piston rod is typically made from hardened stainless steel. This material choice ensures exceptional strength and resistance to bending or deformation, allowing the gas strut to support heavy lids reliably. The hardened stainless steel piston rod also minimizes friction, ensuring smooth and efficient operation.

3. Seals and O-Rings:

To maintain the gas pressure and prevent leakage, stainless steel gas struts incorporate seals and O-rings. These components are typically made from high-quality elastomer or rubber materials capable of withstanding the pressure and temperature conditions within the strut. Seals and O-rings play a crucial role in ensuring the gas strut's longevity and preventing gas leakage, thereby maintaining consistent performance over time.

4. Stainless Steel End Fittings:

The end fittings are the components that connect the gas strut to the lid and the frame or structure it supports. In stainless steel gas struts, end fittings are typically made from stainless steel as well. These fittings provide the necessary strength and stability to securely attach the gas strut to the lid and the supporting structure. The stainless steel end fittings also offer excellent resistance to corrosion, ensuring the longevity and reliability of the gas strut assembly.

5. Nitrogen Gas Charge:

Gas struts rely on pressurized gas to provide the necessary force for supporting heavy lids. Stainless steel gas struts are typically filled with nitrogen gas, known for its stability, non-reactive nature, and resistance to temperature changes. The nitrogen gas charge is carefully calibrated to meet the specific force requirements of the application, ensuring optimal performance and consistent support for heavy lids.

Stainless steel gas struts are a reliable and durable solution for supporting heavy lids, offering exceptional strength, corrosion resistance, and longevity. The main components of a stainless steel gas strut, including the stainless steel cylinder, hardened piston rod, seals and O-rings, stainless steel end fittings, and nitrogen gas charge, work together to provide reliable lid support in various applications. Understanding these components and their functions enables us to appreciate the engineering behind stainless steel gas struts and their essential role in countless industries.