The Manufacturing Process of Stainless Steel Cabinet Handles

Stainless steel cabinet handles are widely used in homes, offices, and commercial buildings due to their durability, corrosion resistance, sleek appearance and reasonable price. The production process of stainless steel cabinet handles involves several steps to ensure the highest quality and efficiency. Let's take a closer look at the manufacturing process of stainless steel cabinet handles.

1. Design and Planning

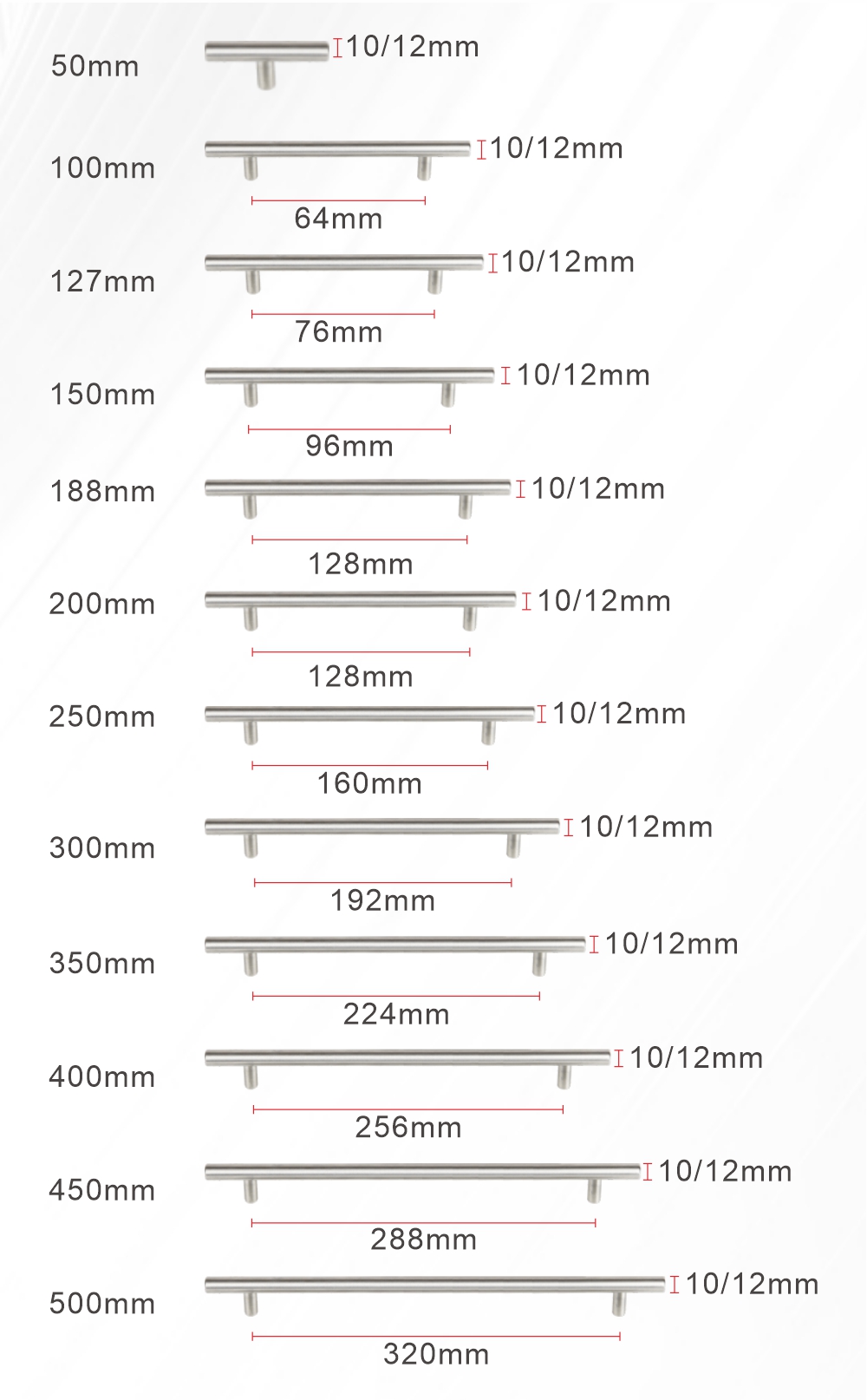

The first step in the production process is the design and planning phase. Designers create sketches and 3D models of the handles, considering factors such as ergonomics, aesthetics, and functionality. According to the place of the application, they also determine the sizes, finishes, and materials to be used.

2. Material Selection and Cutting

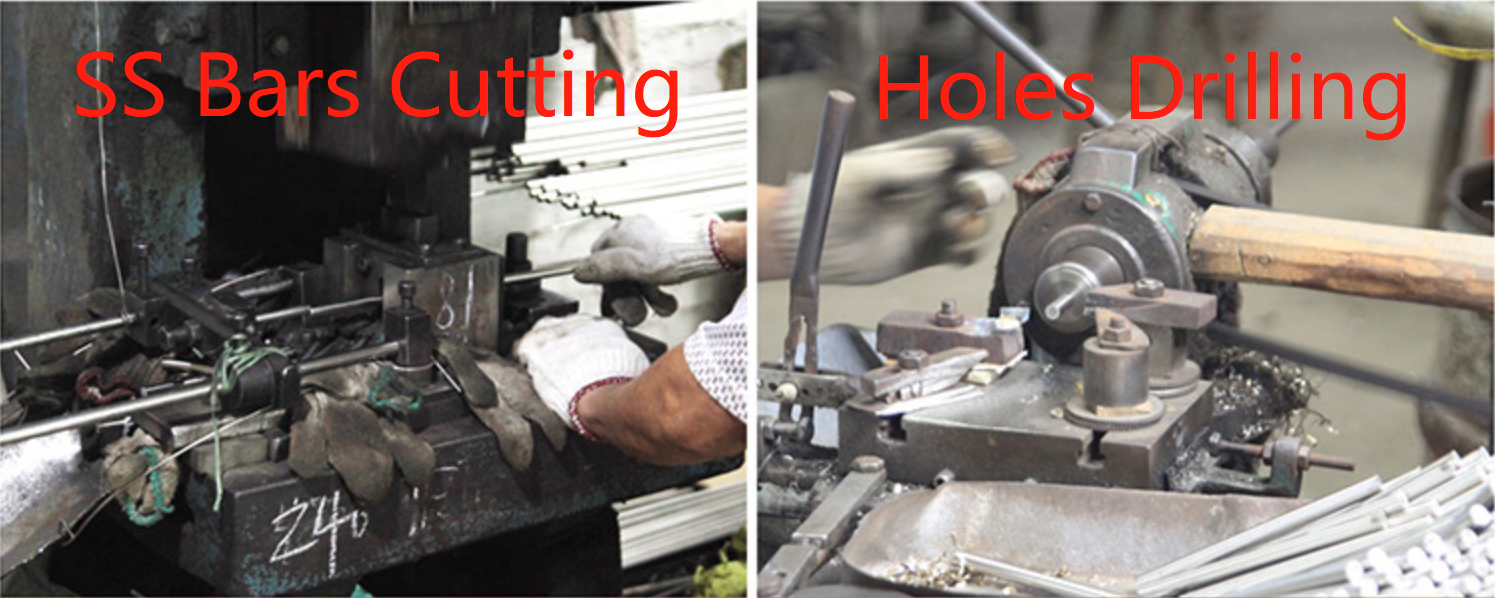

Stainless steel, known for its excellent corrosion resistance and strength, is the primary material used for handles. Manufacturers carefully select high-quality stainless steel bars, ensuring they meet the required standards and specifications. Once the material for stainless steel cabinet handles is selected, it is cut and shaped according to the design specifications. This can be done using various techniques such as laser cutting, water jet cutting, or mechanical cutting.

3. Welding and Assembly

The cut stainless steel bars need to be drill holes to create connections. After that, the individual components of the stainless steel cabinet handles are welded together. Welding ensures the strength and stability of the handle. Any additional components, such as screws or decorative elements, are also assembled at this stage.

4. Surface Finishing

Surface finishing plays a crucial role in enhancing the appearance and durability of stainless steel handles. Various surface treatment techniques are employed, including polishing, brushing, or electroplating with different colors as requested. Polishing gives the handle a smooth and shiny surface, while brushing creates a matte or satin finish. Electroplating can be used to apply a layer of chrome or other decorative coatings to enhance the durability.

5. Quality Control

Throughout the manufacturing process, strict control of the quality is implemented to ensure that the stainless steel cabinet handles meet the required standards. Inspections are conducted at each stage, checking for dimensional accuracy, surface treatment, and overall quality. Any defects or imperfections are identified and rectified before the handles move on to the next stage.

6. Packaging and Distribution

Once the production process is complete, the stainless steel cabinet handles are carefully packaged to protect them from damage during transportation. Stainless steel cabinet handles are labeled and stored in warehouses before being distributed to retailers or directly to customers.

In conclusion, the manufacturing process of stainless steel cabinet handles involves design and planning, material selection and cutting, welding and assembly, surface finishing, quality control, and packaging. Each step is crucial in creating high-quality and exquisite stainless steel handles that meet the demands of customers. Through meticulous craftsmanship and high focus on details, stainless steel cabinet handles are produced to enhance the functionality and aesthetics in various settings.